PCB Quick Turn Services Handle Large Volume Orders

As PCB fabrication and assembly processes have evolved over time, many different options have been introduced for reducing lead times. Quick turn services, for example, leverage advanced technology to dramatically accelerate production timelines. However, achieving such acceleration requires a delicate balance that must be struck between maintaining quality and keeping costs low.

In the realm of pcb quick turn services, choosing a provider with the right production capacity is critical. A company with a lengthy list of satisfied customers is a good indication that they have the resources to fulfill orders quickly and efficiently.

Additionally, look for a manufacturer with an excellent customer support system. A responsive team can help you keep your project on track and ensure that all deadlines are met. Inquire about how they prioritize customer support and whether they have a dedicated team that’s solely focused on responding to client questions.

How Can PCB Quick Turn Services Handle Large Volume Orders?

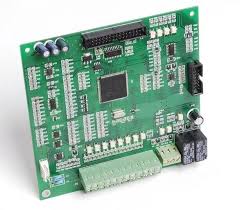

A reliable PCB quick-turn service should be able to produce a wide range of different types and designs, from simple one-layer boards to complex multilayer circuits with multiple connectors. Choose a provider that has experience working with different industries and applications so they can understand your needs and provide you with accurate estimates. They should also be able to offer you customization options that align with your design specifications and manufacturing processes.

Look for a PCB quick-turn service that offers competitive pricing and transparent cost structures. This way, you can easily compare prices and choose a supplier that offers the best value for your money. Request detailed quotes that clearly outline all materials, production, testing, and additional services expenses to make a more informed decision. Lastly, opt for a provider that has established relationships with suppliers and partners in the industry to reduce overhead costs.

One of the primary drivers behind the demand for PCB quick turn services is the rapid pace of innovation in industries such as consumer electronics, telecommunications, automotive, and medical devices. Companies operating in these sectors are constantly under pressure to introduce new products or enhance existing ones to meet evolving customer demands and stay ahead of competitors. In such scenarios, any delay in PCB production can have cascading effects on the entire product development cycle, leading to missed deadlines, increased costs, and lost opportunities.

Moreover, the rise of prototyping and low-volume production has further fueled the need for quick turn PCB services. Startups and small businesses, in particular, rely on rapid prototyping to iterate on their designs quickly and validate concepts before scaling up for mass production. By leveraging quick turn services, these companies can reduce time-to-market, iterate faster, and minimize the risk of costly design errors.

In addition to minimizing production costs, quick-turn PCB services should also be able to maintain quality by employing efficient testing protocols. Streamlined tests can detect issues and correct them without significantly delaying the production process. This includes identifying and rectifying errors at the component level, such as open circuits, shorts, resistance, capacitance, and more. Additionally, they should be able to test their products in a variety of operating environments to ensure that the final product performs as intended in real-world conditions.